Welding technologies

Welding Assembly technologies

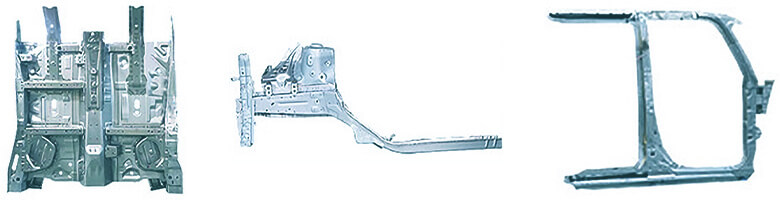

D-ACT have highly-qualified technologies which our customers request for

complicated automotive large components.

(ex. Front floor pan, Front side panel, Side Inner Panel Assembly)

Feasibility study to improve the quality of pruduct's

drawings in the early vehicle development phase.

D-ACT can join the development in the early vehicle development phase of auto

manufacturers, and, verify the assemblability and weldability by the simulation

("Virtual Factory"), based on these prototype drawings.

We can clearify the problems quickly, and take on the suggestion for more efficient

welding/assemblying processes actively.

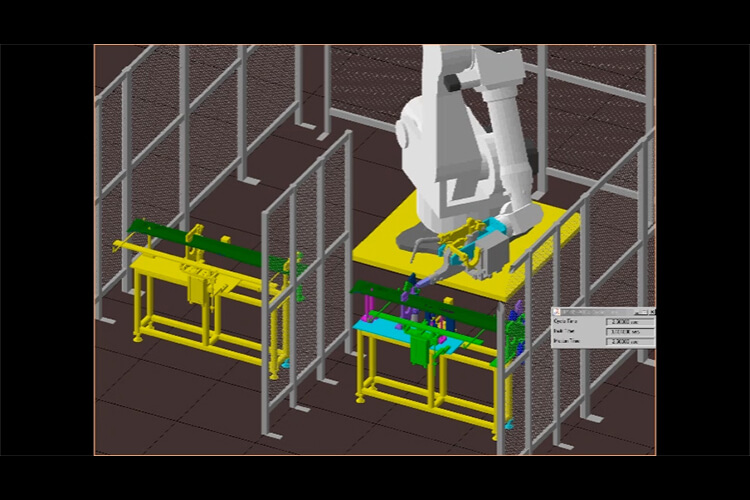

Verificaton of the assemblability and weldability by "Virtual Factory"

With the visualization by 3D, we can improve the investigation level for the operating

position of robots and insertion of welding guns.

And we can shorten the production preparation leadtime with optimum purchasing and

layout of welding robots.

![image:Investigation of operating range [Welding robots]](/assets/img/technology/laser-img-02-01.jpg)

[Welding robots]

Optimum layout of welding robots by 3D simulation

![image:Investigation of operating range [Welding guns]](/assets/img/technology/laser-img-02-02.jpg)

[Welding guns]

Spot welding guns by 3D simulation

To realize the minimum cycle-time, with simultanious operation of welding robots (including material handling)