Stamping

technologies

Stamping Process

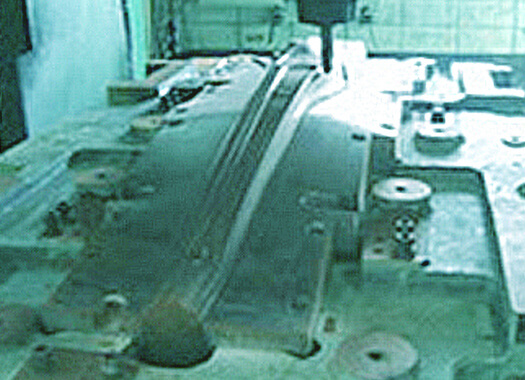

There are a variety of stamping methods depending on the characteristics of the product.

The transfer stamping method in which a single automated press operates multiple dies and sequentially stamps the product to completion is suitable for mass-producing products with a complex form that require multiple steps to make. The tandem stamping method is especially powerful when producing small quantities of large products or products with a simple form that require only a few steps.

There is also the blanking stamping method for single procedures.

With our wide range of manufacturing facilities, we are able to establish a stable manufacturing environment which allows us to respond to our customers' various needs.

Efforts to improve the integrity of the blueprints at the development phase of vehicles

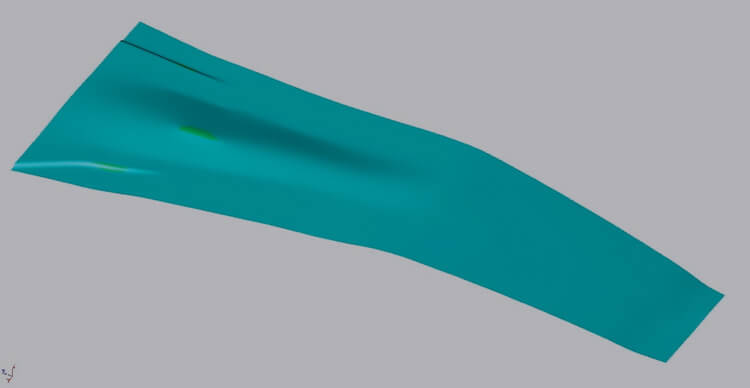

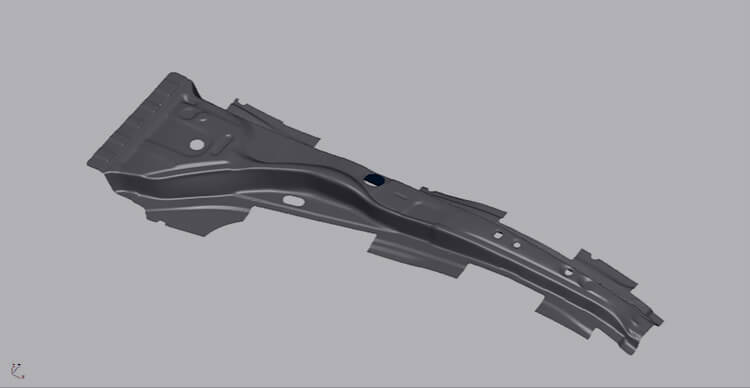

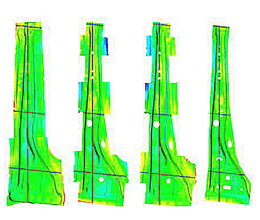

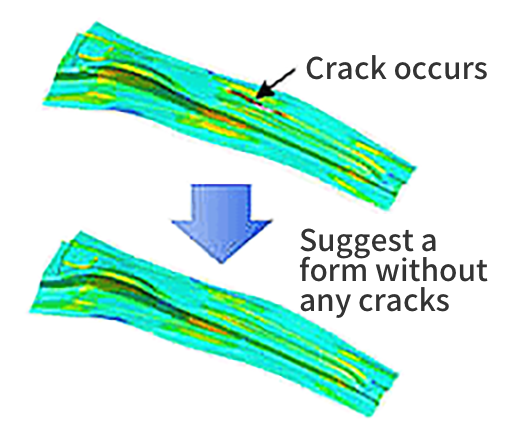

We are involved with the manufacturing of a vehicle from the development phase. With the draft blueprint as a foundation, we use CAE to assess material efficiency, formability, and changes in precisions.

We identify the problem in a short amount of time and actively suggest ways to improve material efficiency and formability.

(cracks and wrinkles)

Production Planning

We are able to manufacture products with short lead time and low costs and use the best suited methods because we carefully consider quality and productivity, reduce the number of steps, and improve material efficiency.

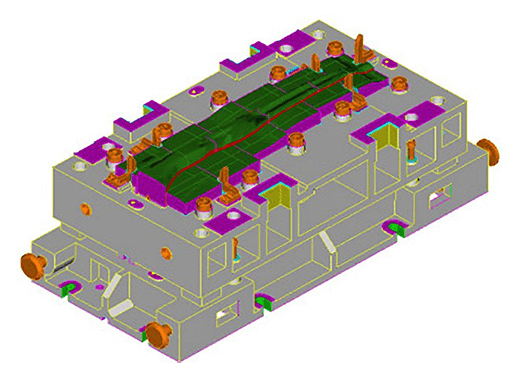

Design and Production

We use 3D CAD to design our products.

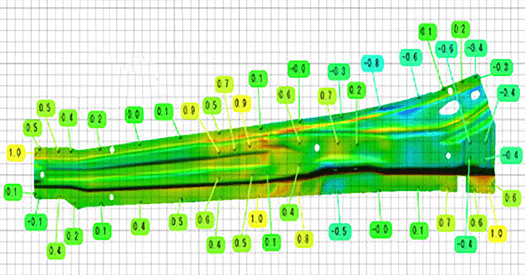

Mass Production Quality Assurance

We use coordinate-measuring machines to ensure quality.